Some companies chose us as a Partner for their printing due to our professionalism, discretion and reliability. Thanks to our expertise and to the collaboration with our Partners, we know how to advise you in the design of your packaging and how to give you a fast and efficient service, which is essential to stay competitive on today’s market.

Thanks to our expertise and to the collaboration with our Partners, we are able to advise you in the design of your packaging and give you a fast and efficient service, which is essential to stay competitive in today’s markets.

ALBA is an ISO 9001 certified company, chosen by professionals working in the mass market retailing.

Many years of activity, supported by continuous investments to stay in step with the market needs.

Prompt response to the Customer’s needs, with increasingly high-performing products.

We print using flexographic presses with customization up to 8 colours

We guarantee to our Customers accurate, detailed images and colour fidelity in reprinting as well. Moreover, we store every order in an electronic archive, in order to have them available for reprinting. The flexibility of our production system enables us to deliver your orders even in 10 working days.

The flexographic printing offers a quality which is similar to the rotogravure printing, but it gives the advantage in terms of cost flexibility, above all with reduced and diversified quantities.

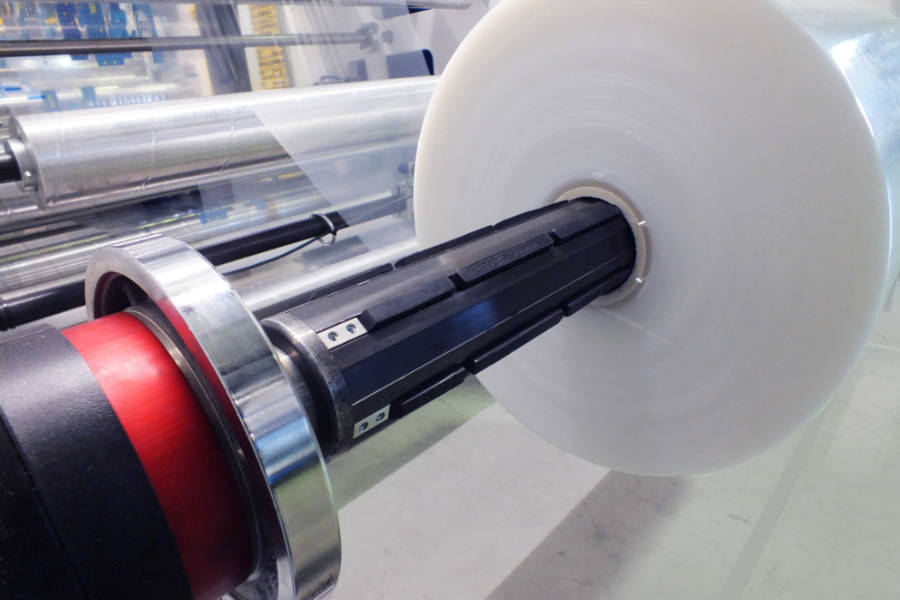

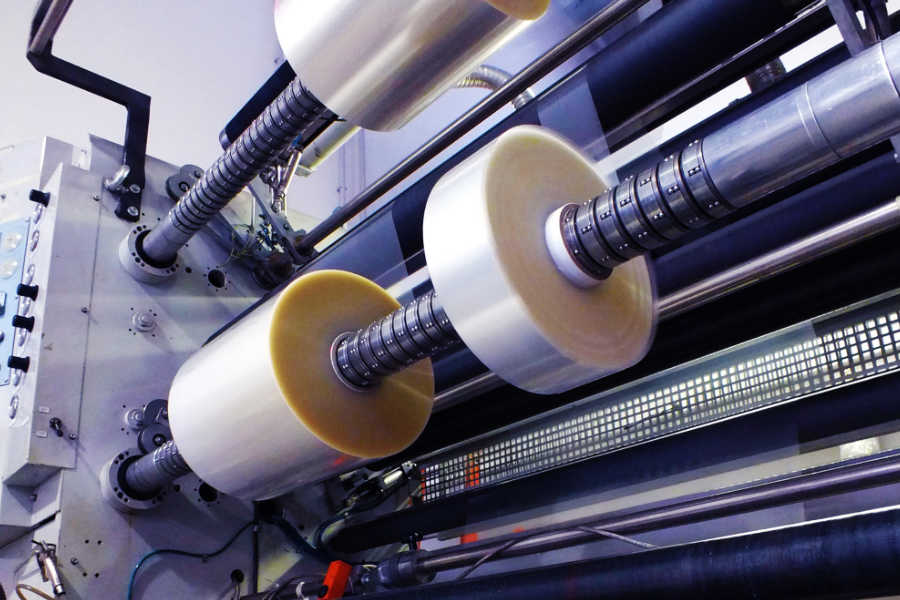

To provide a high-performing and resistant product, it is possible to laminate various materials. This kind of packaging mainly concerns food industry, because it offers a barrier both against external agents and ink migration and extends the shelf life of the product.

In addition to the traditional laminated in PE and PP, organic based film can be laminated, for example with paper, using solventless glue for a reduced environmental impact.

Using reel splitters, we can manufacture precisely sized products, also in small quantities, to meet our Customers’ needs.

The cutting process is guaranteed both in terms of the cutting itself and accuracy of the size.

The welding process is carried out by automatic machines, supported by several optional components (euroslot, zip, adhesive strip, etc.) to customize the product in terms of type and dimensions.

The assigned employees, at that point, verify the product’s compliance with the specifications (dimensions and resistance), and packs it in specific boxes.

The wares are stored in our warehouse, following the manufacturing process in order to avoid damages or degradation of the materials.